| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Packaging Type | Corrugated Box |

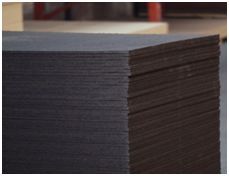

| Thickness | 4 mm |

| Length | 10 Meter |

| Click to view more | |

Product Details

Swastik Pipe Wrapping Tape is a hot applied bituminous tape for corrosion protection as per IS: 10221, it is specially formulated corrosion resistant bitumen compound provides high penetration and high resistance to ageing. Swastik Pipe Wrapping Tape comprises of high tensile strength thermo-fusible HMHDPE film on both the sides. 2 mm Pipe Wrapping Tape is five layer without fiber glass inner core, whereas, 3 / 4 mm thick Pipe Wrapping Tape is seven layer tape with two inner cores; top core is of tough 45 gsm fiber glass and the bottom core is of 15 micron high tensile strength HMHDPE.

APPLICATION :

- Coating material for drinking water pipelines, fire fighting pipelines, raw water pipelines in thermal plants etc.

- Applied on buried and immersed pipes, fittings and appurtenances to protect them from high corrosive environment

ADVANTAGES :

- Coating material for drinking water pipelines, fire fighting pipelines, raw water pipelines in thermal plants etc.

- Applied on buried and immersed pipes, fittings and appurtenances to protect them from high corrosive environment Application

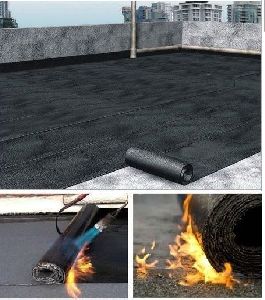

APPLICATION METHODLOGY :

- Remove dust, flakes, oil, grease or other loose foreign particles by blasting, wire brush or compressed air.

- Leave 200 mm from pipe ends for welding joints. Coat and wrap such left over part of pipe at site after welding and hydro testing.

- Apply Primer on cleaned surface at 0.30 L/m2 to get DFT of 30 microns. • Allow the primed surface to touch dry, which may take 5 - 15 minutes.

- show the flame of butane gas torch on to the surfaces till it becomes glossy-smooth.

- Apply SWASTIK PIPE WRAPPING TAPE on the primed surface. Provide overlap of 25 mm between two adjoining layers.

- Wrap spirally and apply sufficient tension to ensure good adhesion and avoid pockets and bridging to meet holiday detection requirement. Tape joint shall face downward on outside of lap joint.

- Complete necessary welding and testing of the joint before coating.

- Recommend to apply at the time of pipe erection and lowering inside trenches to avoid any damage.

HEALTH AND SAFETY :

- Use goggles and hand gloves during application

- Clean hands with warm water after application.

STORAGE :

- Keep under shed away from heat. Do not stack more than three rolls in one column.

Technical Specification

| TEST | VALUE |

| Softening Point | 105±5 |

| PENTRATION @25ᵒ C | 43891 |

| Filler, % | 20-30 |

| Tensile Strength | |

| · Lengthwise for 2 mm | 70 |

| · Crosswise for 2 mm | 50 |

| Elongation, %, | |

| · Lengthwise for 2 mm | 100MIN |

| · Crosswise for 2 mm | 100MIN |

| Holiday Test, KV | |

| ·For 2 mm | 4.5MIN |

| ·For 4 mm | 12MIN |

| Tensile Strength | |

| · Lengthwise for 4 mm | 250 |

| · Crosswise for 4 mm | 80 |

| Elongation, %, | |

| · Lengthwise for 4 mm | 15MIN |

| · Crosswise for 4 mm | 15MIN |

Looking for "Pipe Wrapping Tape" ?

Explore More Products